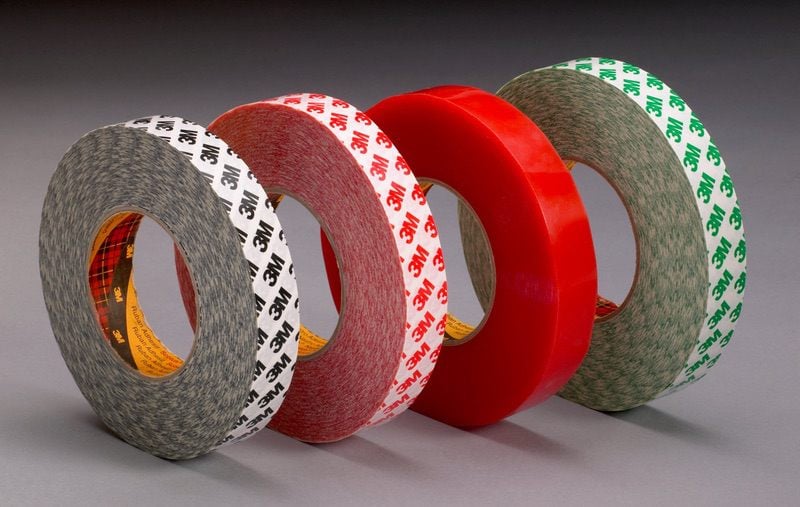

3M double-sided tape: a versatile solution

Small rain lays great dust. There is no better proverb to describe the double-sided tape of 3M. This group of products was made with the promise that it will stick well to any surface, and that we can stick even two different materials together safely and for a long time.

What is the main point of 3M double-sided tapes?

The unique property of double-sided tapes – which is already illustrated by their names – is that a pressure sensitive adhesive can be found on both sides of the tape, allowing two surfaces to be stuck together with the tape between them. The size of the material carrying the adhesive can vary from a thin film to a fraction of millimeter, but it can be even significantly thicker than that. These products can have the same adhesive on both sides but also different adhesives to meet the bonding requirements of different surfaces.

Advantages

These tapes have a compact size (for example Scotch brand is famous for the snail-shaped product), materials of different surfaces can be stuck together easily, and they protect the materials stuck together from moisture as well. If you need to stick two surfaces together as quickly as possible, this is the best solution and the one readily available for immediate use.

The thicker type

Basically, there are two groups of double-sided tapes. The first group includes the thicker types, such as 3M™ VHB™ tape, which is an adhesive for industrial use. 3M VHB tape is created by using acrylic foam, which is viscoelastic, that is very flexible, but it can maintain its strength quality, while efficiently fitting to any object.

The properties of acrylic foam to absorb energy and to reduce stress allow it to perfectly fit to any surface and even to move with the item it is connected to. In addition to this, it provides an extremely durable adhesion on every surface, moreover, it can absorb every hit combined with its flexibility qualities, so it is perfect both for static and dynamic actions. In this adhesive tape, there is a strong adhesive mix, which results in its strong and long-lasting effect.

It can be used in a variety of ways

In transportation, on the side of vehicles, they resist extremes of cold and heat, they tackle moisture and UV, and they are a better fixing solution than rivets or screws. We can find thicker double-sided tapes in the construction sector, where the tapes stick one flooring onto the other. Their use in electronics – such as in the production of high-resolution televisions – proves that they meet even the highest requirements, but they can be found almost as an “invisible” adhesive in apparatus as well.

The thinner types of 3M double-sided tape

Thin adhesives make it possible to hide massive fasteners during design, but also to establish bonds of industrial strength. However, despite being thin, they have outstanding performance, which is the reason for these types being used in electronics, in creating the internal space of vehicles, in graphic arts or in sports equipment designed for more demanding use.

These even have a type – such as 3M™ 100MP high-performance acrylic adhesive tape – which was designed for an operating temperature of 149°C, and is used for purposes with extraordinary performance, like in pneumatic deicing boots in aircrafts and in lightning protection systems in particular.

Everyday use of double-sided tapes

If we break away from the world of industrial buildings and plants, no average household can spare double-sided tapes. They can be useful in installing durable floor coverings, in carpet laying, in installing insulation or heating mats, but there are very interesting practices as well. One of such uses was when someone fitted a sign on the wallpaper, and double-sided tape was the true solution (with some foam added behind the sign).

According to professional renovators and builders, when removing such types of tapes, we have to pay attention that the tape forms an acute angle at most to the surface. This might seem to be a slow, persnickety work requiring a lot of patience, but this is the only way to avoid that undesirable pieces remain on the wall.

In the last 40 years, 3M can present the production of thick double-sided tapes of 7,620,000 km. These are very powerful figures, which proves the expertise and experience of the company. In addition to this, several other products can be found in their range: black, white, colored, transparent tapes, but also spray, waterproof and universal tapes are available, which means a very wide variety for outdoor and indoor use.

More articles

Flanker Plusz Kft.

Contact Details

Boti Street, 100.