Case sealer: keep all your goods safe

Products are typically transported in boxes, but it matters how the box shipped is sealed. If this is not done professionally enough, the goods can be damaged during transport, which is both inconvenient for the customer and financially damaging for the company. The ideal case sealer automates this key operation. Let's see how!

Packaging technology is a rather colourful field that has undergone huge changes over the last decades. With the growth of online shops and the rise of online shopping, speed is becoming increasingly important, but fortunately not at the expense of security.

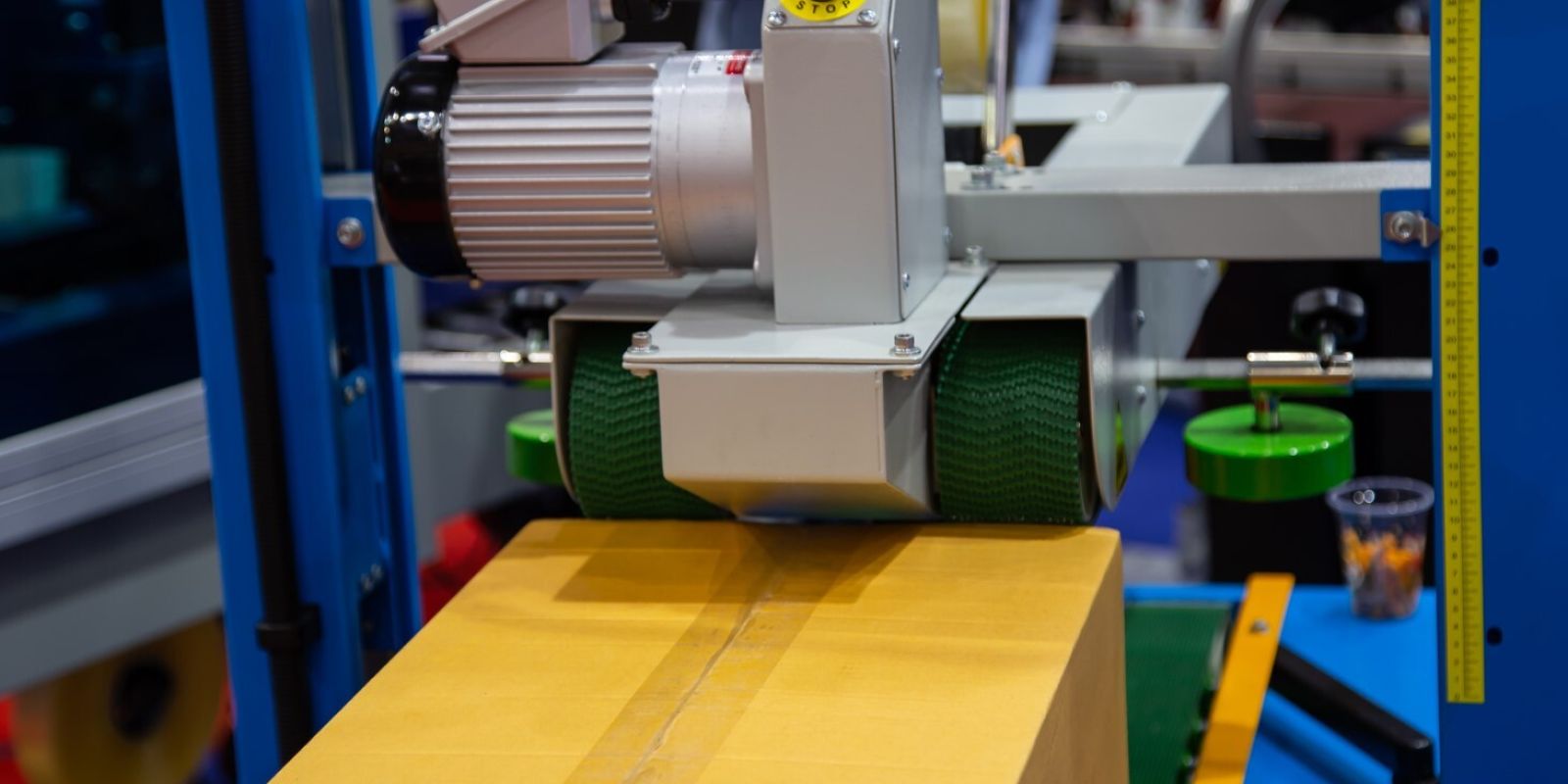

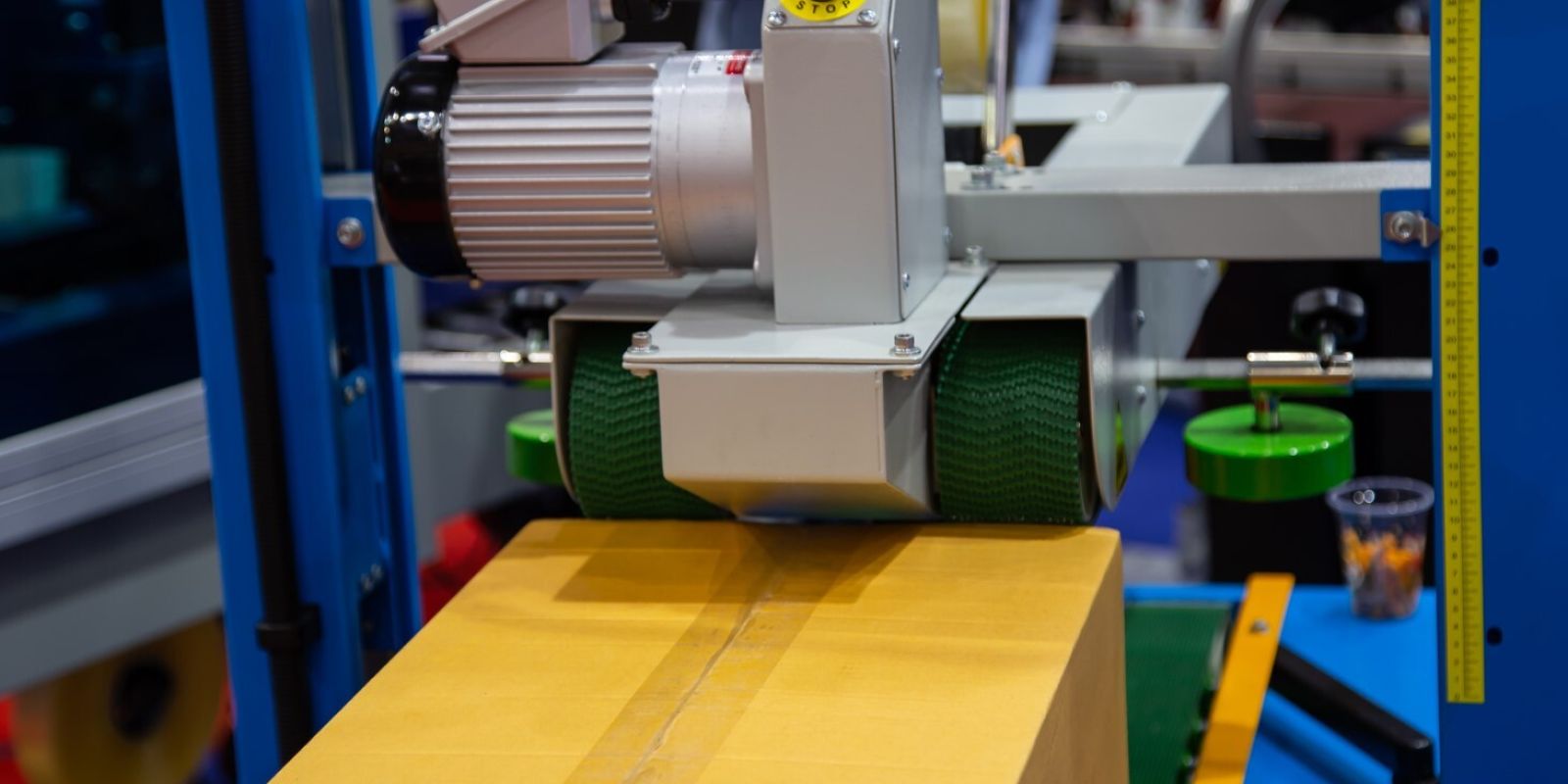

Thanks to innovation, packaging can now be made even more efficient with the help of complex systems. Boxes are assembled by the box erecting machine, so workers only must concentrate on filling them, if not automatically. Once the goods are in the box, it is sealed by the case sealer machine and the finished packages can be sent to the warehouse on a conveyor belt.

What is a case sealer?

During the sealing process, the workers insert the open box into the sealer that automatically seals it and loads the next box. Thanks to the automated sealing process, the quality of the packaging is guaranteed. Case sealers are durable and low-maintenance solutions when it comes to packaging. Flanker offers a wide range of case sealers, such as the 3M-MaticTM 7000A 3PH 380/415V case sealer ACCUGLIDE 2+2IN, or the 3M-Matic™ 8000A 1PH 220/240V case sealer ACCUGLIDE 2+2IN.

The advantage of a case sealer is that it is flexible in adapting to the size of the boxes, and automatically detects the parameters of the box and adjusts based on these parameters.

Sealing is possible with several types of case sealers. There are manual adhesive tape applicators, semi-automatic bottom-up sealing machines with manual or automatic adjustment, semi-automatic box erecting and filling stations, and automatic box erecting machines with bottom-up adhesive case sealing.

Selecting the optimal tape is crucial during the process. There are many types to choose from, for example brown, transparent, paper, and of course different sizes. See what box sealing tapes are available from Flanker!

What aspects should you consider when choosing a case sealer?

Choosing the right case sealer is not a simple task. Let's look at the factors you should consider before making your decision.

- What is the type of the box? What are its parameters? What is the material? Cardboard? Corrugated?

- Are all boxes the same size or are the sizes different?

- How is the box closed? Will the folding of the tabs be automatic? What width of the tape is needed, and will there be overlapping?

- What capacity is required? What are the performance level requirements? How many boxes will need to be closed per day?

- What will the box contain? How much load will the box sealing machine be subjected to?

- What other requirements are there? Will it fit into an existing system?

In which cases is it appropriate to use a case sealer?

There are cases when a case sealer can significantly facilitate and speed up the packaging process. For example, webshop operators, and manufacturers who need to package their products safely in the shortest possible time.

What are the advantages of a case sealer?

The biggest advantage of case sealers is their speed and efficient operation. A semi-automatic machine can seal as many cans in 5 minutes as it can manually in 30 minutes. It logically follows that it increases packaging capacity significantly, by up to a third. Operation is simple and fast, just switch it on and it's ready to work. It helps to optimise the amount of adhesive tape used and thus reduces costs.

What does a professional, good case sealer look like?

The following requirements can be made of modern case sealers:

- Practical: a case sealer is easily variable, can be built in both left and right-hand versions, and its modules are interchangeable.

- Safe: the construction of a good quality machine is simple, with few components, which also means that it requires little maintenance and therefore minimum downtime. Its operation is safe in terms of both efficient production and operation.

- Offers functional variability: modern case sealers can be easily expanded with other modules to meet your needs.

With the rise of online shopping, the issue of appropriate packaging is also gaining in importance. However, by using a quality case sealer, you can be sure that the parcel you send will arrive undamaged.

More articles

Flanker Plusz Kft.

Contact Details

Boti Street, 100.