Reclosable Fastener: a perfect solution for all loose situations

Nowadays fasteners are essential parts of everyday life. The products rapidly gained popularity thanks to their practicality and simplicity. Depending on the types, the use may vastly differ. Fasteners are used as essential tools in many fields from textile to industrial application. Let's see what you need to know about the product!

The invention of the reclosable fastener

The inventor of the reclosable fastener, Georges de Mestral, was inspired by nature and especially by the thistle. In 1941, after a hunting trip, he was picking thistles stuck in his trousers and his dog's fur. He observed how these plants could stick so strongly and cling to the fabric with so many hooks. In 1951, after refining the idea he finally patented his invention which he called the ‘Velcron’. Over the past 70 years, the concept of reclosable fastener has not changed. On the other hand, technology, materials, and the fields of applications have expanded considerably.

Where should fasteners be used?

The question may arise in which cases a fastener is the best choice. In general, a fastener is recommended when it is important to fix two elements firmly while keeping easy removal optional. Typical examples could be various panels, advertising tools, information boards, instrumental panel elements and so on. It is important to emphasize that fasteners are very durable and weatherproof so they can be used outdoors too.

Which types of fasteners exist?

Fasteners can be categorised in several ways. The main differential characteristics are the ways of attachment to the surface. The first group are the so-called sewable fasteners which can be easily fixed with a needle and thread. These are mostly used for textiles.

Another major group of fasteners are the self-adhesive ones. In this case, the backs of the two strips are self-adhesive as they are coated with adhesive material which allows them to be attached to many surfaces. They are mostly used when the substrate is a non-sewable surface such as wood or plastic.

What is a self-adhesive fastener?

The main difference between a self-adhesive fastener and a plain fastener is the strong glue strip. It is easier to apply the self-adhesive fastener because the strip and the other side do not require sewing. This way, the product provides a dismountable and lockable, high-strength fastening method that makes it ideal for industrial applications.

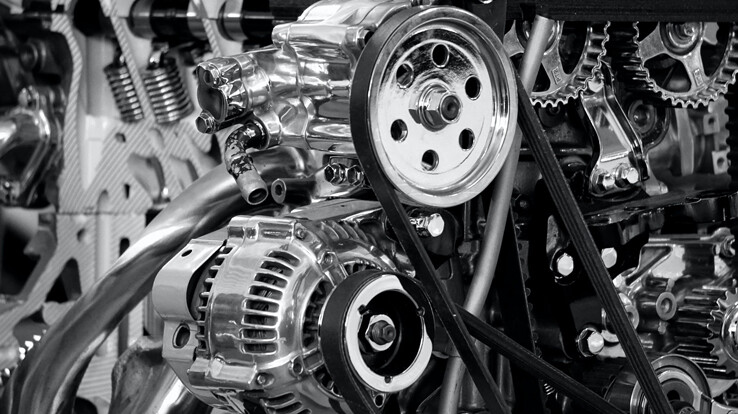

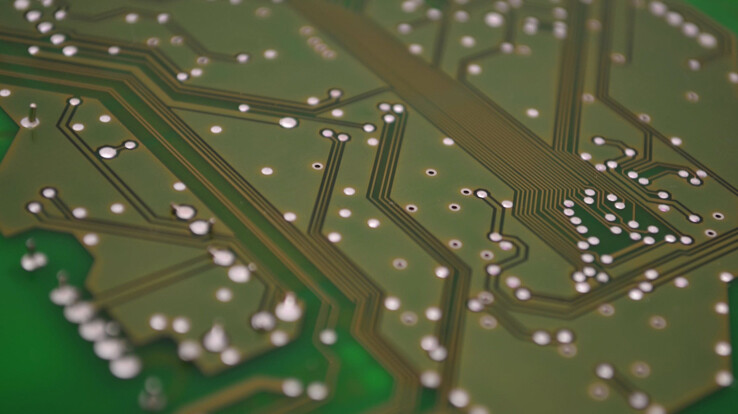

The 3M™ Dual Lock™ industrial fasteners, for example, provide twelve times stronger adhesion than any classic loop-clamp fastening method due to the mushroom-shaped spikes that interlock the two parts of the fastener. In a previous post we described this technology.

The advantages of self-adhesive fastener

The self-adhesive fastener has several advantages compared to other fastening methods. Let's have a look at them!

No-drill bonding

Fasteners are equipped with mechanical fixing mechanisms. A big advantage of them is that there is no need to drill or damage the surfaces. Because of their nature, fasteners can bond surfaces together without any screw. Similarly, a self-adhesive fastener can also be of great service when the classic fastener cannot be sewn.

Easy installation

Applying the self-adhesive fasteners is child's play. No tools or complex measurements are needed, just the removal of the protective film on the back of the self-adhesive fasteners.

A solution for every need

It matters what kind of surfaces you want to bond and how strong adhesion you need. That's why there are many types of self-adhesive fasteners. For example, some are transparent, some have a rubber-based adhesive back, and some have a low-profile size.

Discreet design

Self-adhesive fasteners can be discreetly used to bond surfaces. There is no trace of the fastening until dismantle. Not to mention, if the fastener is transparent, then the colour of the underlying surface is also visible, making the fastener less noticeable.

Self-adhesive industrial fasteners provide strong bonding. They are an excellent choice to attach different types of surfaces, especially when it is important to have a bonding that is quick to create, easy to dismantle and yet still strong. Check out what Flanker has to offer!