Abrasive discs for disc sander: what, when and how?

The disc sander, or flex, is a real all-rounder in the workshop. It can be equipped with a wide range of accessories which makes it useful for many tasks such as sanding, cutting or polishing. There are several versions of abrasive discs. Let's see which one to use when!

How should you choose a disc sander?

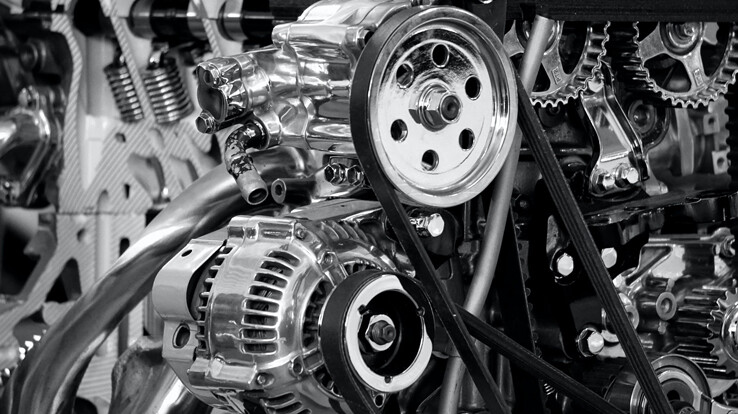

There was a time in Hungary when almost all disc sanders were made by the German company ‘Flex’. Thanks to that, this type of grinder is most commonly referred to as a ”flex” in general. The disc sander can be translated as ‘corner sander’ in Hungarian, however, it is not suitable for grinding corners. It is called so because it is the opposite of a straight-shaft grinder. While in a straight-shaft grinder the motor and the disc are on the same horizontal, in a disc sander the motor and the disc are at right angles. Today there are several types of products, so it's a good idea to get further information before purchasing.

The higher the speed of the device, the stronger it is. This strength is often essential, but sometimes, for example, when it comes to polishing, it can be too much and damage the surfaces. Should you often encounter such cases then opt for a grinder with an adjustable speed. They are a bit more expensive, but if the high speed could damage the machine or the material, there is no other choice.

Grinders are single-handed below 150 mm and double-handed above that. This is because the power of the latter is quite high so two hands are needed to hold them safely.

There are both wired and battery-powered grinders. It is understood that the battery-powered versions allow for much more freedom and these products are easier and more comfortable to move around with. However, you should be aware that with frequent use, the batteries will lose capacity over time, so they will run for a shorter and shorter time.

With grinders, particular attention must be paid to safety. Therefore, it is advisable to choose a model with a soft start. The reason for this is that when you switch the device on, it only gradually increases the speed which is safer and more efficient in terms of power consumption. Some models also have special sensors so that should the machine overload or overheat, it will automatically switch off and can only be restarted when it has cooled down.

Finally, as far as different types are concerned, there are also grinders specifically designed for DIY and also professional use. These can differ in price and performance because it does matter whether you use a disc sander once every six months or several times a day.

Abrasive discs for the disc sander

You can start the planned work when you attached the disc to the machine. Discs for disc sanders have different types depending on whether you want to use them for various surfaces such as wood, metal, plastic, ceramic, iron, paving stone, concrete or simply for polishing.

The basic accessories for the grinder are the cutting disc and the sander disc. Their diameter and material vary according to the surface but their thickness may also vary within this range. While the cutting disc is 2.5-3 mm, the sander disc is 4-6 mm thick. They are usually colour-coded to indicate what they are for: blue for cutting metal, red for grinding metal and green for grinding stone. If you are grinding with a plastic disc, you ought to use sander discs or fibre sheets of different grit sizes which can be attached with a gum disc or fastener. This is the abrasive disc that is also used in different colours: red is suitable for sanding metal and wood, and grey is for sanding stone.

Today, there are also so-called diamond-grinding discs that take the cutting process to a new level as they are very powerful, have a high capacity, and can even cut stone building materials.

Usually, the discs also have numbers and sometimes warning labels on them. These provide information on the outside diameter of the disc, the thickness, the diameter of the centre hole and the speed of rotation.

How to use the disc sander

Using a disc sander is not difficult but there are some basic rules to follow. For example, it's important not to remove the protective cover on the machine which is fitted for safety reasons: it protects the user during cutting and other dangerous operations. It is also important to hold the disc sander with two hands and fix the material/workpiece with a clamp. Moreover, if the machine is used as a saw, it is essential to wear safety goggles.

Mistakes can arise, especially when the machine is used as a saw (i.e. cutting) and full force is applied. However, this is not the best way as it can damage the material and the disc too. It is better to let the machine do its work under its weight and not to force anything.

Accessories for disc sanders

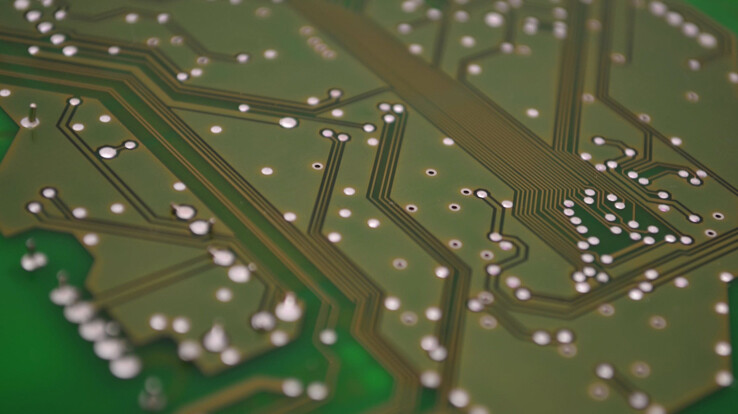

There are now several accessories available for disc sanders. Once the grinding disc is removed, the new adapter can be easily attached. Some accessories can be used to turn the grinder into a circular cutter, a hole drill or even a handsaw.

More articles