Hot melt adhesive: a quick and easy solution when it comes to glueing

Hot melt adhesive solutions are very popular, which is no wonder, as they are easy to use, reduce production costs, increase productivity, and minimise waste. The hot melt adhesive is based on resin, which is a solid material that turns into a liquid state when heated, making it much easier to spread. Let's find out what you need to know about these kinds of adhesives!

What is a hot melt adhesive?

The history of adhesives dates to ancient times and the first adhesive is thought to have been sealing wax, used to seal important documents, but it was also used to glue leather, letters, and paper. Over time, synthetic materials were introduced, the first being phenol-formaldehyde resin, which was mainly used in the woodworking industry. In the 1950s, epoxy resin became also widely used, which had excellent strength properties.

Hot melt adhesive is an easy-to-handle and effective adhesive, based on ethylene vinyl acetate, polyamide, and polyolefin copolymer. It is essential to know that adhesives based on polyurethane undergo a cross-linking process after pressing and cooling. The adhesive is available in several types and sizes. For example, in light yellow, brown, gold/yellow and transparent. It can be purchased in the shape of granules, cubes, and sticks. It can help to make glueing processes very quick and efficient.

The hot melt adhesives are suitable for quickly forming bonds between the glued elements. They require a special device called a glue gun. The function of the glue gun is to melt the loaded solid glue by increasing the temperature. The speed at which the adhesive bonds between the elements depends on the thermal conductivity of the surface materials to be bonded and the amount of adhesive.

Once the adhesive has been applied to the surface, it is advisable to apply light pressure on both sides until it dries, making the bond more secure. As the material cools it bonds the surfaces together.

In terms of bonding, it has the advantage of providing a very stable bond with good impact strength and, during the cooling process, it can be flexibly formed.

How does a glue gun work?

Glue guns are available in several designs. You can buy the simpler models from a simple DIY shop, but some are designed to stand up to industrial conditions. These guns are powered by electricity, and the adhesive can be dispensed by pressing and holding the appropriate button.

Some very small models fit into the palms easily. Their main function is to heat the glue, typically PVC-based, to between 100 and 150 degrees Celsius. These can melt only a small amount of glue at a time, so are suitable for small areas and delicate work.

There are also standard 50W guns, which require the insertion of an 11 mm glue stick, which is discharged in molten form through a 2 mm nozzle. Some models are supplied with several heads, i.e. the shape of the nozzle can be varied.

To choose the right glue gun, you need to think about what you want to use it for. For example, it is important to know what temperature it can be heated to, as this will determine what kind of stick can be used for glueing. This also affects the temperature of the melted material, which in turn affects how it solidifies and how adhesion develops.

It is important to get the appropriate glue stick for the gun because if you don't, the glue will not melt properly thus affecting the outcome.

If you want to buy a glue gun for hobby use, lower-priced models are available, but if you want to buy a glue gun for frequent and continuous use, it is advisable to buy a more advanced one.

Hot melted adhesives: areas of use

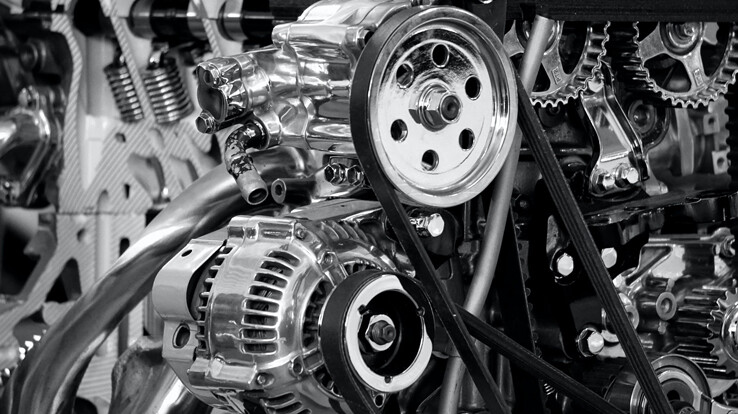

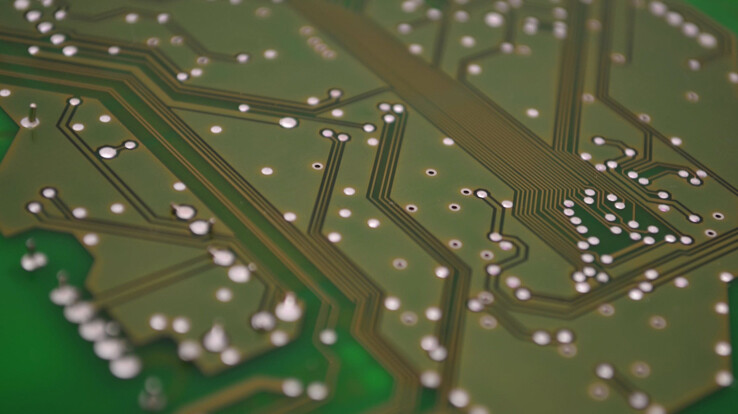

Hot melted adhesives loaded into a glue gun has several advantages, such as being very practical and easy to use, and can therefore be used in a wide range of situations where glueing cannot be avoided. It is widely used in the paper industry, packaging, woodworking, certain stages of furniture production, the hygiene industry, textiles, the automotive industry, and industrial-level printing.

These adhesives can also be applied to wood, veneer, cardboard, leather, fabric, plastic, polyester, steel, and aluminium.

Flanker has been at the service of various industries for more than 20 years. Have a look at our web catalogue!