The clean and strip cut disc – how to use it properly?

A clean and strip cut disc is a special tool designed for cleaning, smoothing and sanding surfaces of different materials. The discs have a specially designed abrasive surface that allows them to effectively remove dirt without scratching or leaving other surface defects. Selecting and using the right cleaning disc is key to increasing the efficiency of your workflow. These tools not only make cleaning faster and easier but also significantly reduce the risk of material damage.

Using the clean and strip cut disc

The correct use of cleaning discs not only determines the quality of the result but also our safety. First, always read the manufacturer's instructions that come with the disc. When you start working with the disc, make sure that the disc is properly secured, as a loose disc will not only make your work worse but also pose an accident risk.

It is important to choose the right size and grain size disc for the job. For example, if you want to remove paint, a fine-grained disc may be ideal, while for rust or welds, you will need a coarser-grained disc.

Safety considerations

Safety is a primary concern when using clean and strip cut discs. Wear safety goggles and gloves to avoid injury. Also, if dust or other harmful substances may be released during the work, use a respirator.

Make sure that your work area is well-ventilated and that there are no flammable materials nearby! Before turning on the power, check that the tool is stable and does not move, which is particularly important when the disc is working at high speeds.

Maintenance of the clean and strip cut disc

Maintenance of the cleaning discs is essential for long life and efficient operation. Clean the discs regularly to remove dust and other dirt. This can be done using compressed air or a soft brush. Avoid cleaning with hard objects, as these can damage the surface and grains of the disc.

Cleaning discs need to be replaced when they no longer provide the desired performance. If the disc is visibly worn, fragmented or does not leave a good mark on the workpiece, it is time to replace it.

With frequent use, the cleaning discs' grains will gradually wear away, so over time they will no longer be able to effectively remove paint, rust or other contaminants. Regular inspection and replacement will ensure that we always get the job done to optimum quality.

Common mistakes when using a clean and strip cut disc

Wrong choice of disc

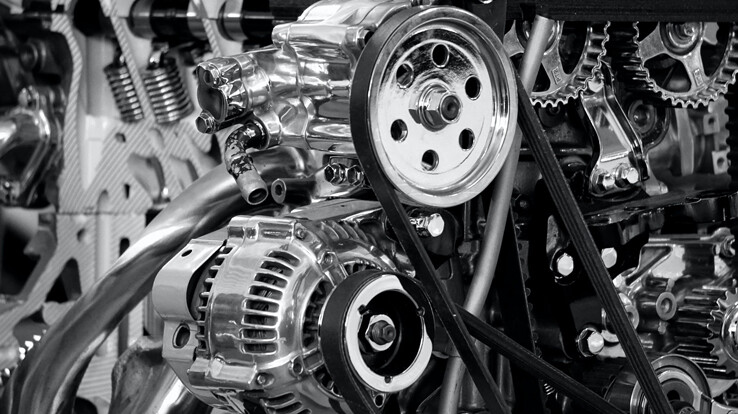

The wrong choice of clean and strip cut disc can cause many problems for the user. If you are working on the bodywork of a car and you have chosen the wrong type of disc, it can easily damage the paint or metal surface, leading to additional repair costs. In the woodworking industry, a similar mistake can cause a rough or uneven surface or cracks in the wood, which can reduce the quality of the final product.

One of the most important steps in selecting the right reel is to know exactly what the application is and what type of material it is to be used for. It is worth seeking professional advice if necessary. Furthermore, it is important to always buy reels from a reliable source that are of the right quality and have been tested.

Improper storage of discs

Improper storage of discs can shorten their life and negatively affect their performance. For example, if they are stored in a humid or damp environment, they can quickly rust or mould, which can reduce their overall efficiency. Temperature fluctuations can also be detrimental, as the discs can become deformed or damaged.

To preserve the quality of the discs, they should be stored in a dry and cool place. It is advisable to avoid direct sunlight and to use containers that protect the discs from mechanical damage. It is important not to touch the reels closely and always keep them in their original packaging if possible.

Improper use

Improper use of cleaning discs can be dangerous not only to the workpiece but also to the user. If the disc is used with too much pressure, it is easy to damage the workpiece, and the disc can be damaged. An inappropriate speed can also be harmful, as too high a speed can lead to rapid wear, overheating or even breakage.

First, it is important to always use the reels under the conditions recommended by the manufacturer. Pay particular attention to the speed and pressure used. Always wear appropriate protective equipment such as goggles and gloves. If a fault should occur, stop work immediately and check the condition of the discs, replacing them if necessary. Ultimately, thorough preparation and following the rules will help avoid mistakes and ensure a longer life for your cleaning discs.

Looking for the right tools and materials? We're waiting for you in Flanker's webcatalogue! Look around and find what you need to work efficiently and accurately!