The pneumatic disc sander

Pneumatic tools are very efficient due to their unique functioning. Pneumatic sanders can be used to remove surface defects and unevenness effectively. In this article, we've gathered all the relevant information that you need to know about these tools.

What are pneumatic tools?

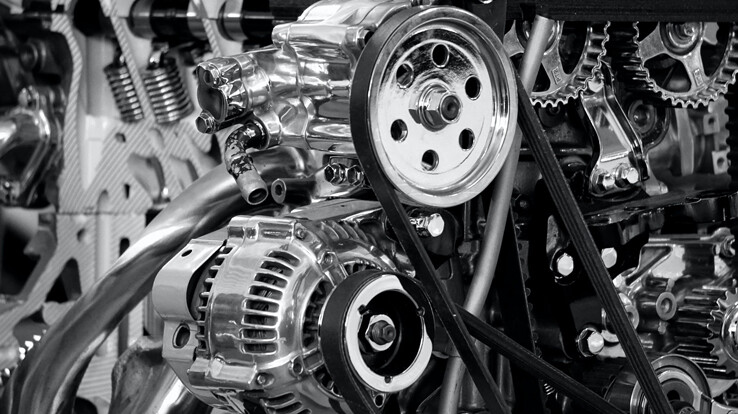

Pneumatic tools are air-powered. What this means in practice is that they build up an air system to which you can connect various special tools, such as a chisel, drill, angle grinder, stapler, impact wrench, or even a nail gun.

The great advantage of such air-based systems is that they can be installed on the columns at a much lower cost, to which various tools can then be easily attached.

Pneumatic disc sanders

A pneumatic disc sander is a tool that is commonly used to reduce and smooth the surface of various types of materials. The principle of operation is that the machine uses air pressure to generate the energy by which the grinding head rotates, causing the abrasive cloth, sanding disc, or sandpaper to perform a grinding or sanding motion.

These pneumatic sanders help to perform various sanding operations efficiently and effectively. Their use is advantageous as they are powerful and reliable thanks to the pneumatic power source.

Types of pneumatic sanders

Orbital sanders

Orbital grinders are very versatile tools, suitable for grinding and polishing surfaces of wood, metal, and other materials. Thanks to the rotary movement, smooth sanding can be achieved, whether it is for more vigorous or finer sanding.

Belt sanders

Belt sanders are longitudinal sanders, suitable for demanding and uniform sanding of larger workpiece surfaces. The performance of the machines and the quality of the sanding are determined by the grain size of the abrasive used.

Disc senders for covering angles

These special types of sanders can be used for a variety of applications. They are generally used for grinding and cutting surfaces of materials. Their compact, practical design and the different sizes of their discs allow them to handle almost any type of material.

Vibratory sanders

Vibratory sanders perform an irregular rotary motion, making them ideal for fine grinding of large surfaces. They are also used for grinding edges and corners. Their compact and lightweight design makes them convenient to use and ideal for places where access is limited.

Die grinders

Die grinders or sanders have different sizes and types of attachments, which allow the use of different grinding discs or cutting discs. The grinder can be used for grinding, smoothing, or cutting surfaces of metals, wood, or other materials. Pneumatic die grinders are widely used in various industries and trades, such as automotive, woodworking, engineering, and construction. In addition, the ergonomic design and light weight allow working for longer periods without fatigue.

Benefits of pneumatic sanders

Safety

In most cases, sanding tools are used in the work area, in the workshop, where dust can collect, liquids can spill or even conductive metals can be in the immediate environment. These are all sources of danger, especially when working with power tools. With a pneumatic sander, however, there is no need to worry about damaging the cord or accidentally cutting it, and the equipment itself does not pose any electrical hazard to the user.

Compact design

Pneumatic tools, including grinders, are typically preferred because they are compact and easy to use. They are strong, yet lightweight, thanks to the aluminum frame that houses a durable steel pneumatic motor and a composite handle for added comfort.

It is therefore much lighter, easier, and faster to work with, making the work much more efficient. For comparison, while an electric sander weighs just over 3kg and has a power output of 710W, a pneumatic sander weighs just under 2kg and has a power output of 1700W.

Efficiency

The main indicator of a sander is its material removal capacity, i.e. the time it takes to remove a given amount of material to be sanded. It is generally true for sanders that the best performance is achieved at a given power. Modern machines have an adjustable speed, so when you increase the speed, the airflow, the speed, and, of course, the speed of the abrasive increases.

Durability

Pneumatic grinders are very robust, they can withstand cutting, grinding, deburring, weld preparation, seam removal, and grinding. Electric grinders have several limitations, such as the fact that they cannot be used in humid environments and are significantly exposed to the negative effects of dust and abrasive particles in the air. Pneumatic devices, on the other hand, are more robust, can be used in humid environments and dust does not affect the engine. This makes their use more advantageous in foundries where extreme temperatures are encountered, in drilling rigs where water, salt, and cold are a challenge, and in windmill blade manufacturing where composite particles are a threat.

Trustworthiness

Pneumatic grinders are characterised by their tremendous durability, longevity, and reliability. Their simple design also means they are easy to service and maintain. Generally speaking, maintenance is required after 60-120 hours of operation, and the carbon brushes should be replaced at the very least. In the case of professional or industrial machines, the carbon brush should be replaced even less frequently, every 200 hours in the former case and every 2000 hours in the latter. With less servicing, the machine will be up and running for a shorter period, making it more cost-effective to operate.

Flanker's core values are reliability, cooperation, and dynamism. This is the spirit in which we work every day and strive to serve our customers with the highest possible quality. We have been in the market for more than 20 years, providing professional and complex solutions to industry players. Have a look around our web catalogue!