Threadlocker for secure bonding

The main purpose of screws is to hold together and bond the mating surfaces. However, over time, the threads of the screws can loosen, and wear out due to weight and force. By using thread-locking adhesives, we can prevent the loosening of the screw joints. This material contributes to ensuring that the screw does not come off due to vibration or impact. Let's see what you need to know about threadlockers!

What is a threadlocker?

A threadlocker is a liquid substance that fills the gaps in the screw threads, ensuring that the screw cannot loosen due to movement, vibration, or wear and that the bond remains intact. The application of this one-component adhesive is simple, without creating mess or contamination, and its effect is long-lasting. Due to these properties, it is widely used in various industries.

The bonding time for the adhesive ranges from 20 to 60 minutes, depending on the characteristics of the surfaces, but it may take 12 to 24 hours to reach full strength.

What are the advantages of threadlockers?

Threadlockers have numerous advantages that make their use worthwhile. Here are the most important ones:

- Applicable to any thread: It doesn't matter what type of thread it is; the adhesive spreads in the thread, fills it, and creates a secure bond and seal. This is a great convenience for professionals as they don't need to deal with specialized seals, and the same solution can be applied in every situation. The versatility also leads to lower inventory costs.

- Prevents corrosion: By permanently securing the connection, the adhesive prevents corrosion from damaging the metal.

- Bonds to all surfaces: Threadlockers can bond to any surface, even passive surfaces such as aluminum, coated surfaces, or stainless steel.

- Can be used on slightly contaminated surfaces: The adhesive can create a proper bond without the need for a perfectly clean surface. If there is mild contamination on the material, the adhesive can still exert its effect and create a secure bond.

- Creates a vibration-resistant bond: Some elements are subject to significant vibration. In these cases, screws can easily loosen if they are not secured with adhesive in the thread. Typical examples are screws in pumps, presses, and gearboxes.

- Can be assembled with hand tools: Despite creating a strong bond, the components can be easily disassembled using the appropriate hand tools.

- Clean application: The adhesive is typically equipped with a suitable-sized dispenser, making it easy to use anywhere, anytime. Its use does not involve excessive mess or dirt; only a few drops are needed to reinforce the screw joint.

Applications of threadlockers

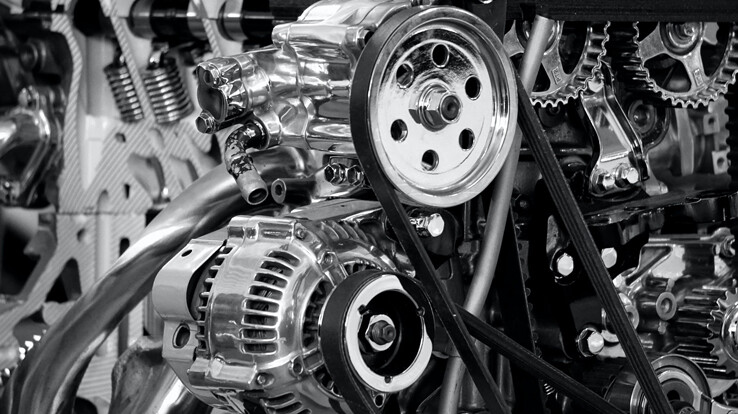

Adhesives of this type can be used in various industries wherever screw reinforcement is needed. Typical examples include automotive manufacturing where resonance caused by the engine or engine block can loosen screws holding the vehicle's components, such as those in the suspension system. The adhesive prevents the screws securing vehicle parts from loosening, preventing them from falling off and causing damage to other parts of the car. Noisy and moving components can cause wear, exposing the car to unexpected malfunctions.

Threadlockers from Flanker

For over two decades, Flanker has been providing comprehensive solutions for industrial players. Our product range includes structural adhesives, including threadlockers and screw-locking adhesives such as 3MTM Scotch-WeldTM TL70 Threadlocker, which is a one-component, high-strength adhesive that ensures a durable bond. A classic threadlocker is the medium-strength 3MTM Scotch-WeldTM TL42, which allows fasteners to withstand vibrations, impacts, and corrosion. Another variation is the 3MTM Scotch-WeldTM TL62, which provides rapid curing. Take a look at the Flanker website!