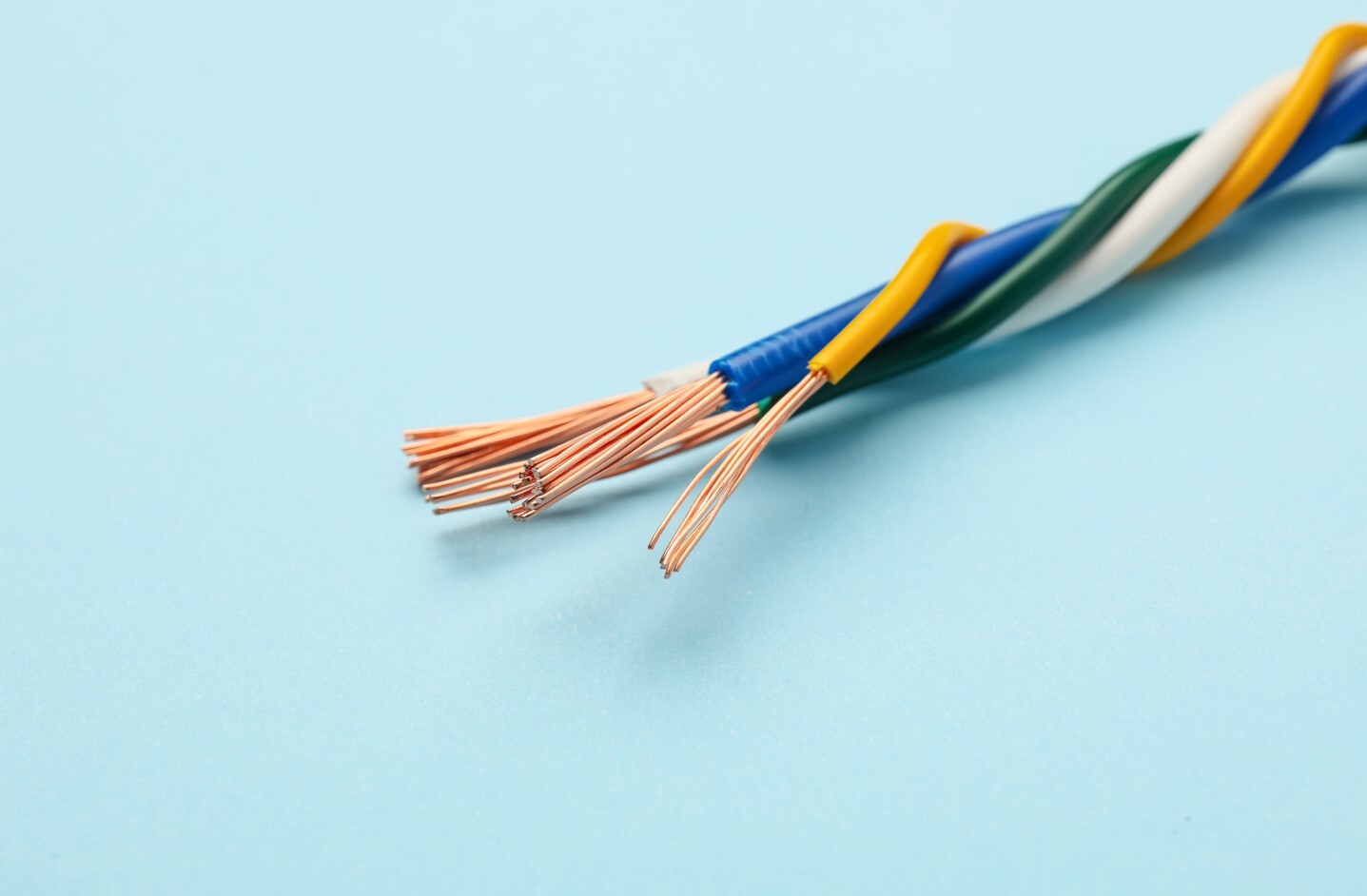

Wire pulling lubricant: smooth cable insertion

To make cable pulling easier, the wire pulling lubricant reduces the friction resistance you experience by up to 80%. Is there a need to use wire pulling lubricants instead of the former soapy solution? Let’s found out!

Applying wire pulling lubricants makes it easier to pull in the cables, avoiding them getting stuck and damaging the insulation surface. Its viscosity is gel-like and most importantly, it leaves behind minimal mess. It makes it much easier to replace cables and pull in a new one. Its ingredients are biodegradable materials that will not corrode pipes or insulation.

What's wrong with the traditional solutions?

There are traditional, cost-effective solutions to make cable pulling easier, such as oil sprays and various soaps. These fulfil the basic function of lubricating cables, in that they all make it easier to lay cables, but it's worth bearing in mind that these are only temporary solutions and can cause more trouble than good in the long run. Unlike wire pulling lubricants, these materials do not disappear completely but remain in the pipe, so if you need to replace a cable or want to pull in another strand, they can hinder the process. What's more, they can even damage the pipe and the insulation of the wires, which can lead directly to a blockage.

Advantages of professional wire pulling lubricants

Using a quality wire pulling lubricant can make the job faster and much more precise. It completely disappears from the pipe, so it does not make it difficult to replace cables later. It is available in a variety of pack sizes to suit your needs. The Flanker webshop offers 0.95 litre, 3.78 litre and 18.9 litre versions. This allows professionals to choose the right packaging for their specific use.

How to use the wire pulling lubricants?

It can be used for pulling into conduits and cable ducts. Especially recommended for communication, electrical, control, signal, and monitoring cables.

Its application is simple. All you need to do is apply the material directly to the cable and then pull it into the appropriate duct or conduit. If on completion of the operation, there is any dirt on the surface, it should be removed with a cleaning cloth, preferably until it has dried.

Avoid contact with natural stones such as granite or limestone. It is worth testing the material before use to ensure that it behaves properly and that we are using it correctly.

More articles

Flanker Plusz Kft.

Contact Details

Boti Street, 100.