Polyurethane adhesive

Polyurethane (PU) glue is a very versatile adhesive, making it a popular choice among our customers. What exactly is polyurethane adhesive, what types are there and when should it be used? Here are the most important things to know.

Polyurethane

Polyurethane is a generic term for materials that are held together by urethane, or carbamate bonds. This versatile polymer material can have different properties depending on the type of material, which makes it suitable for use in construction, furniture, and automotive applications. It is available in various forms, including coatings, foams, and adhesives. Let's find out what you need to know about polyurethane adhesive!

Polyurethane adhesive

Polyurethane adhesive is a synthetic, resin-based adhesive that hardens when it comes into contact with water. As soon as the adhesive is applied to the surface, it starts to expand and the excess can be easily removed with a knife. Achieving the final solid state, a permanent bond can take up to 1 hour, so the materials must be tightly pushed together.

This type of adhesive can be used at temperatures above +15 degrees Celsius. Should you try to use it colder than this, the adhesive's properties may change. It is worth knowing that polyurethane is antiseptic, which means that it prevents mold and fungi from growing.

Let's learn about the benefits of polyurethane adhesive!

It can be used to bond different materials

One of the huge advantages of this type of adhesive is that it can be used to bond different materials together. Whether it's wood, plastic, metal, or any other material, polyurethane adhesive provides a stable bond.

Waterproof and watertight

Although moisture is required for curing, once the adhesive has set, it is no longer damaged by water or precipitation. This is an extremely advantageous property, which allows it to be used outdoors and even as a gap-filling sealant.

Practical use

The characteristic of the adhesive is that it does not cure all at once, but takes about 20 minutes to harden. This is an advantage because, in this time interval, it is still possible to move the materials around and find the right position and setting. Overall, it takes 1 hour for the final bond to form, and this long bonding time should always be taken into account when applying the adhesive.

Gentle

The polyurethane adhesive does not damage the surface of the materials, does not leave marks, and does not bump up. This means that it can be used safely even when laying parquet or wooden floors.

Weather resistant

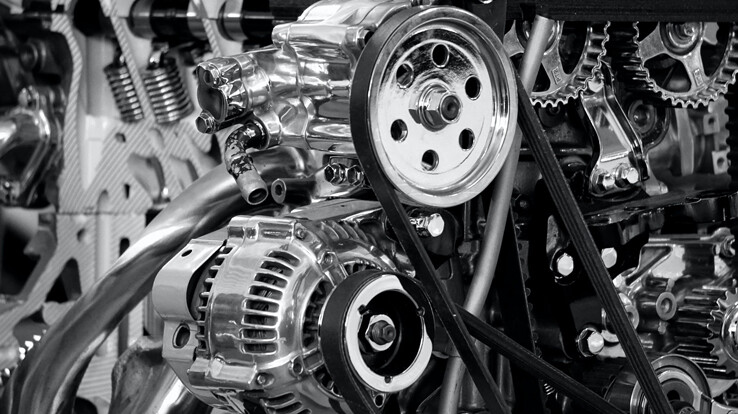

Resistance is a very important property, and polyurethane adhesive is a leader in this respect. It is resistant to frost, air and heat, extreme temperatures, and substances such as petrol and oil.

What can it be used for?

As described above, polyurethane adhesive is a versatile option for bonding tasks. It can be used to glue ceramics, stone slabs, marble, porcelain, and mosaics, and repair swimming pools, boats, and toys. It is suitable for fixing PVC edges, and panels on furniture or windows.

Used in the manufacture of sandwich panels, for fixing artificial grass and rubber mats. An excellent choice when different elements such as timber beams, plinth units, guttering, or plastic need to be joined together. It can also be used for furniture restoration, shoe repair, flooring, and car seals.

The characteristics of the adhesive

Polyurethane adhesive is composed of 10-15 elements, the ratio of which determines the final properties of the adhesive, such as viscosity, adhesion, and curing speed. Different colouring agents are used to give different colours to adhesives for different applications, e.g. amber and brown for wood adhesives, and black or grey for metal adhesives.

Types of polyurethane adhesive

There are two types of polyurethane adhesives: one-component and two-component. What do you need to know about them?

The one-component polyurethane adhesive

These adhesives typically form a flexible bond, adhering surfaces together with a resilient layer that resembles rubber. They are less harmful to health than other adhesives because they contain fewer harmful substances.

It has the advantage of being an environmentally friendly solution that absorbs vibrations, creating a flexible bond rather than a rigid one. The adhesives can be easily resealed and reused later. If they accidentally get on the skin, there is no need to worry, they can be easily removed.

These one-component adhesives are also commonly found in households, used for repairing shoes, and carving. Easy to use, all that is needed to start polymerisation is a little moisture provided by the air or the material to which it is applied.

The two-component polyurethane adhesive

This type of adhesive is made up of two components which, when they come together, start a chemical reaction and form a bond. The two components come in separate packages, so they must be mixed before use. Particular care must be taken to ensure that the correct proportions are used, as this is the only way to achieve a satisfactory result. The polymerisation is not triggered by the moisture but by the other component.

It is essential to be aware that the B component of two-component adhesives contains epoxy resin, which means that it can be harmful to health, for example by causing an allergic reaction.

It is a preferred adhesive for floor tiling, for example, as it can be used to correct minor substrate irregularities. It bonds quickly and creates a very strong adhesion. It is easy to work with and good value for money.

Using the adhesive

With a one-component adhesive, the material is ready to use, but with a two-component adhesive, you start by mixing the ingredients. It is a good idea to remove any dirt, dust, or grease from the material and then apply the adhesive in a thin layer. If you are working with paste, use a spatula to spread it.

The layer of glue mustn't be too thick, i.e. that it is applied thinly. If you are working with a porous surface, apply two coats, wait a few minutes after the first coat, and then apply the next coat.

For a certain period, about 20 minutes, the materials can still move, so when you have found the right fit, fix them. Once the joint is formed, trim off the excess with a knife.

Check out the Flanker range, where you can choose from a wide selection of adhesives!