Furniture wrapping: a new look in an easy way

As well as being the object of utility, furniture can also define our habits and serve as a means of expressing our taste and mindset. They play an aesthetic role in a property, contributing significantly to creating a unique atmosphere. Vintage or much-used, less durable pieces of furniture can wear out over time and need to be renewed. If you want to give your tired furniture a new look quickly and easily, then the best option is furniture wrapping!

There are countless reasons why you might want to give a piece of furniture a new look. It could be that the teeth of time have left their mark on the surface, but it could also be that you're on the verge of a style change, or that the piece of furniture is being moved to another room where it doesn't fit in.

Furniture renewal can be done in several ways, but if you're short on time and looking for a quick, and cost-effective solution, then furniture wrapping is the best option.

What is furniture wrapping?

Furniture wrapping is a process whereby a piece of furniture is simply covered with a special film. This film is self-adhesive in most cases and consists of three main parts. As with stickers, there is a protective layer, the surface itself and an adhesive layer that adheres to the furniture sheet. Self-adhesive wallpaper works on a similar principle and is mostly used for decorating interior surfaces.

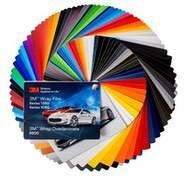

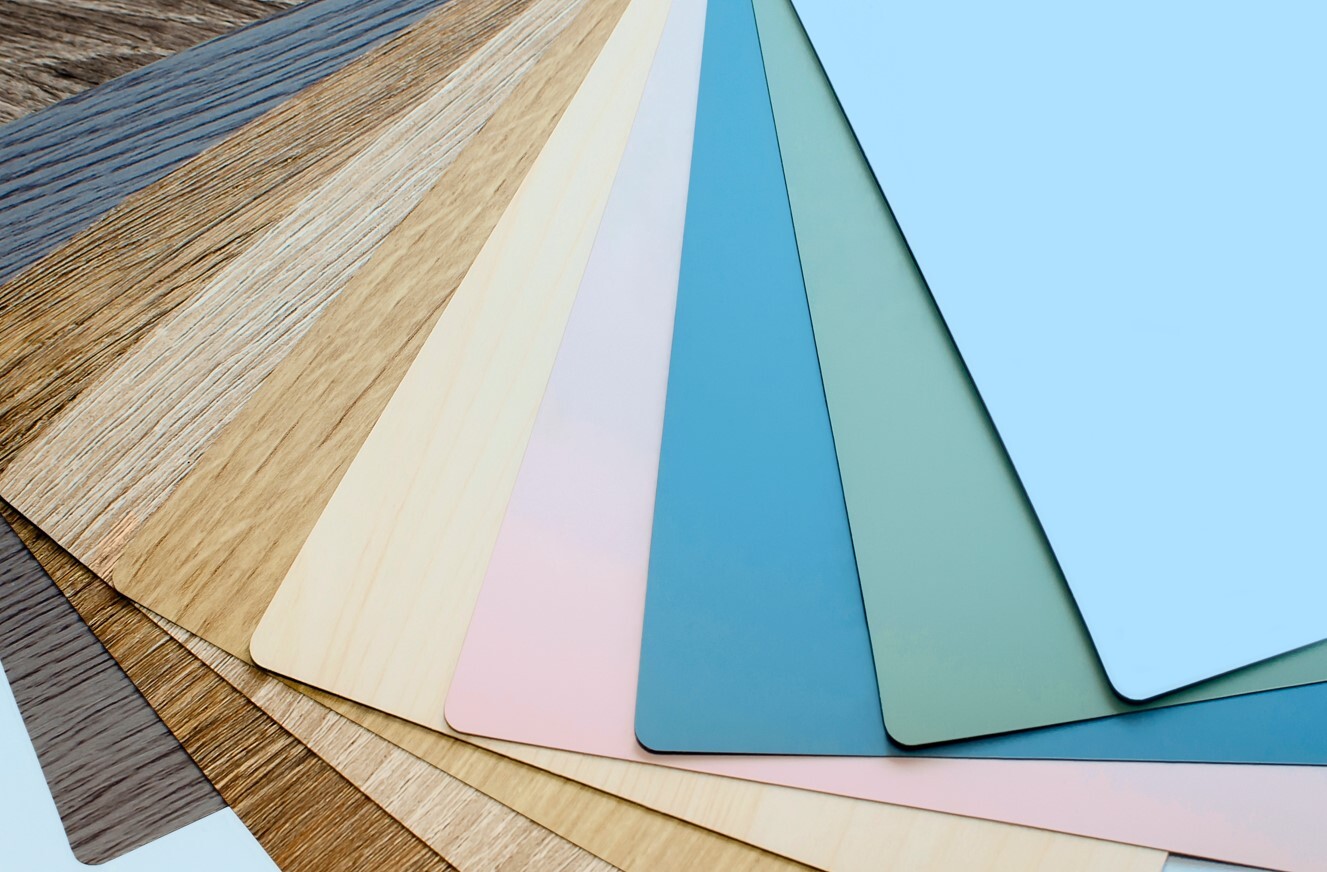

Self-adhesive wallpapers and furniture films are available in a variety of colours, some with a wood effect, some with a stone-like appearance and some with a metallic coldness on the furniture’s surface.

The protective layer is removed during application and its function is to protect the film from external influences. So, for example, when the tiles are placed on the side of a cabinet they must be peeled off.

The purpose of the glueing is to ensure that the film adheres firmly to the surface. It is common to encounter cases where the adhesive tape comes off the MDF surface that has been purchased ready-made, typically the cabinet furniture front. What could be the reason for this?

MDF is wood fibre based and is produced with high-pressure pressing. A huge advantage is that it is easy to handle, simple to paint and foil. Their characteristic feature is that the heat and pressure during application cause the glue to cross-link, which is what binds the film. However, in the case of plywood, the evaporation of the resin can weaken the adhesive, not to mention the fact that adhesion can also be impaired by heat. It is important to note that films by their very nature like to shrink to their original size, which can also cause them to separate from the surface. However, with a little care and the choice of good quality materials, these negatives can be avoided, and a retro-fitted thermal barrier film can ensure a long life.

Some tips for use

- Start small! If you are inexperienced, it is a good idea to start with a simple surface, such as a flat and level surface.

- Clean, then glue! Before you start glueing the film, clean the surface thoroughly, dust and degrease it, as this is the only way to ensure that the film sticks properly to the surface. When cleaning, use a microfibre cloth, as this will attract dirt and make it easier to remove.

- Prime! If the surface of the furniture has not been treated with anything, it is a good idea to start by priming it, i.e. starting with the primer.

- Take it one step at a time! Glueing is not too difficult, but it needs some practice. Firstly, unroll small pieces (10 cm) of foil, as much as you can safely handle. Working from the centre outwards, smooth the foil up so that there is no air trapped underneath. It's best to do this with a special smoothing tool, but if nothing else, a microfibre cloth will do.

Advantages of the self-adhesive film

- The self-adhesive film has both advantages and disadvantages. Here are the advantages that have made this method of furniture refinishing a favourite for many!

- It forms a waterproof layer on the surface of the furniture, meaning that it does not allow moisture to reach the wood.

- It does not emit substances harmful to human health like most paints.

- There is a wide range of product variability available on the market.

- Easy to apply, nothing special, expensive, nor difficult-to-obtain equipment is needed. All you need is the film itself and a trowel.

- The application is not complicated, it requires attention, but it is easy to learn.

Disadvantages of self-adhesive film

Furniture films are very popular, but some problems can arise when using them. Let's look at the disadvantages!

- Wood does not breathe under the film as it completely seals the surface.

- Poor quality foil can deteriorate over time, but good quality foil can last for a long time.

- Damages and other physical impacts will show on the foil, just like on the original furniture board.

Renewing furniture with filming is more cost-effective and environmentally friendly than buying new pieces. Give your furniture a new colour, refresh your interior, liven up your spaces!

- Hits: 911