Sorbents: Working hard for a clean and safe environment

A sorbent is a water softener that can be used to clean up spills of hazardous substances so that they cannot cause damage to the environment or personal injury. In this post, we have collected information on the different types of sorbents and when to use them. Let's see how to get your work area clean after a spill!

What is a sorbent?

The industrial sorbent is designed to absorb spilt liquids and hazardous substances, thus helping to avoid accidents and property damage. In general, it is very light in weight and can absorb liquids very quickly. Let's see what types of sorbents exist!

Types of sorbents according to their material

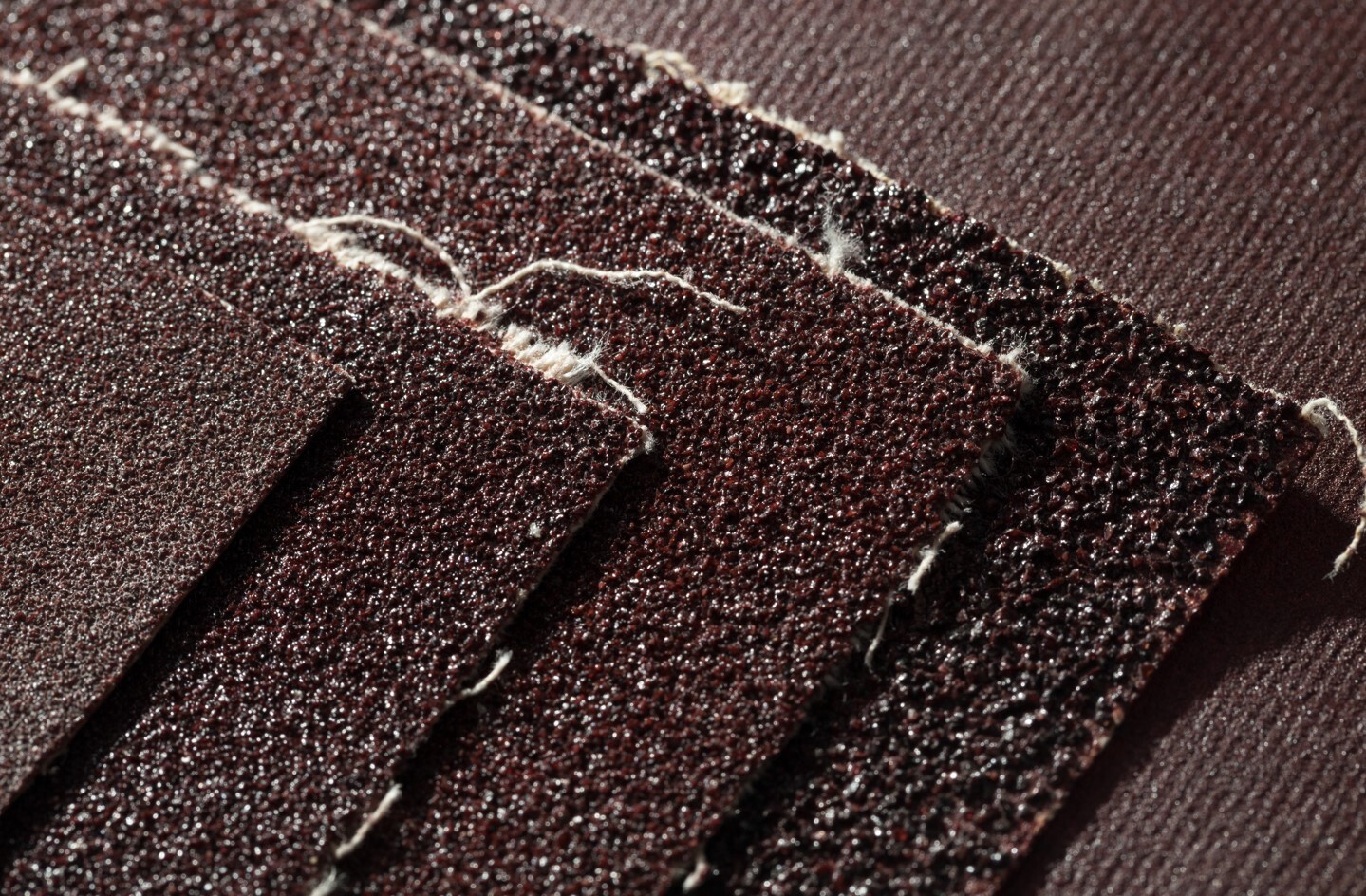

In terms of consistency, there are two main groups of sorbents: textile sorbents and granulates. The main ingredient of textile sorbents is polypropylene, which can bind large amounts of liquid by the fibres. They have a very fast dissolving capacity, which makes them suitable for large volumes of dirt and for preventing leaks.

Granulates are typically made of various minerals and can be used for small to medium spills. They are highly effective on porous and uneven surfaces and in situations where spillage is difficult to reach. The advantage of granules is that they can be used for all types of liquids, but they have the disadvantage that they must be deactivated, in a safe way, after they have absorbed the liquid. In the case of textile sorbents, this means simply throwing them away in the appropriate waste bin, but the granules need to be swept up and vacuumed.

Types of sorbents by absorbable material

In the case of textile sorbents, three further types can be defined according to the material they are intended to absorb. According to this differentiation, there are general, chemical-resistant, and oil-sorbent solutions.

The general sorbent

General sorbents are widely used, but it is important to be aware that if you are dealing with a very dangerous substance, you may want to choose a different type of sorbent. It can also be used for water, weaker acids and oily liquids, although in the latter case the result may not be 100%.

The oil sorbent

For oil spills, it is advisable to use special oil sorbents, which are highly effective at soaking up even the most unpleasant-looking oil spills.

The chemical-resistant sorbent

Chemical-resistant sorbents are specifically designed to soak up dangerous, corrosive substances and poisons, and can be used to remove more aggressive substances with great safety. However, it must be noted that in the unfortunate event of a spillage of a hazardous substance, neutralisation must be carried out first, followed by the clean-up.

The signalling of the sorbents

Sorbents are marked with different lettering to help you find the right type for your situation. The M symbol, for example, indicates that the sorbent has a single layer of absorbent material, but is not resistant to various mechanical stresses. CMC, on the other hand, is much more robust, with a protective layer on both sides of the half-coat. SMS is the most resistant of the sorbents to damage but at the cost of a slightly slower speed of digestion.

In what forms sorbent are available?

Sorbents are available in a variety of forms, including mats, cushions, sorbent sheets and so-called oil sorbent slings. Mini-Booms, for example, are excellent for surrounding barrels with the sorbent, but also for delimiting dirt. Furthermore, pillows prove to be the best choice when it comes to removing spillages under machinery.

What are the criteria for choosing a sorbent?

Choosing the right sorbent is not so easy at first, mainly because of the abundant supply. First, you need to consider what liquids you will be using it for, how uneven the terrain is and whether you need a faster or more resistant material.

Flanker has been supplying products to the printing and paper, packaging, automotive and electronics industries for over 20 years. Should you be in doubt about choosing the right type of sorbent, do not hesitate to contact us. Click here to browse our webshop!

- Hits: 751