Surface protector film: avoid minor damage by applying film!

Surface protection is an essential part of the manufacturing process. During storage, material handling, transport and sales, the surface of manufactured products and objects can easily be damaged, which is not only annoying but can also cause considerable financial damage. However, by using surface protection film, we can prevent these mechanical damages.

What is surface protector film?

Surface protector film, as the name suggests, plays a key role in protecting surfaces. It is a transparent, flexible and easy-to-apply material whose primary purpose is to protect surfaces from minor scratches, impacts, abrasion and dirt. It is highly resistant to UV radiation, which also helps to preserve the original colour and condition of surfaces.

Surface protector film is a versatile product that provides excellent service in a wide range of applications. Thanks to its wide range of applications, it is not only used in industrial environments but also in everyday life.

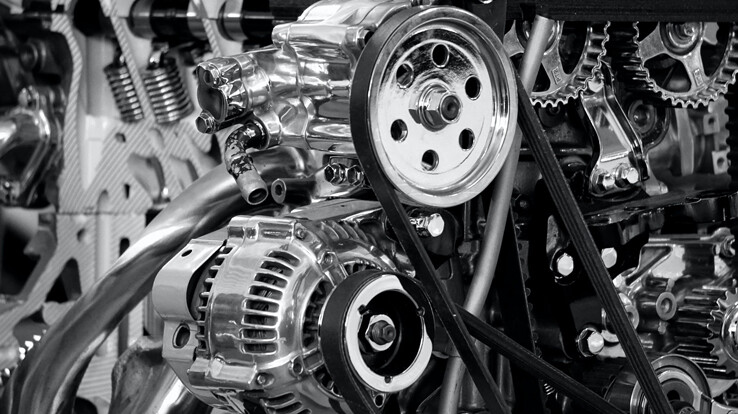

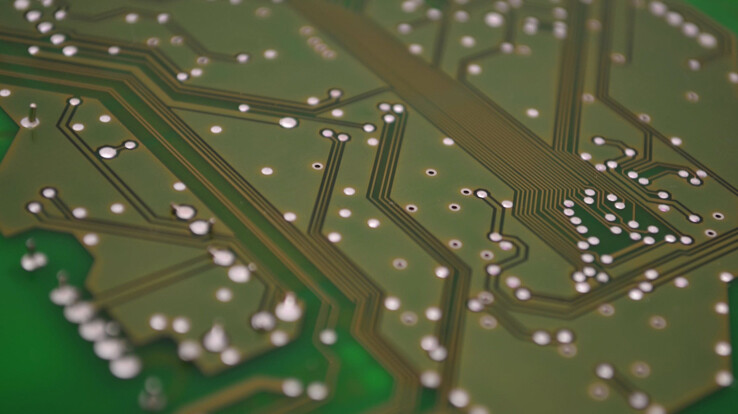

In the home, for example, we can protect furniture, floors and various tools from becoming worn or damaged prematurely. Surface protection film is also often used to protect the bodywork of vehicles. As well as protecting the car from minor stone chips and scratches, its coating can also be a good choice for its appearance. It can be used to protect plastic, wood and metal window frames, for display protection, in the packaging of artefacts, and to protect stainless steel tanks and plastic pressed sheeting.

Why is it beneficial to use surface protection film?

Surface protector film is an excellent way to protect a variety of surfaces, such as vehicle paintwork or displays. Its basic properties include scratch and impact resistance, effectively protecting surfaces from minor damage during everyday use. This allows you to prolong the life of your surfaces and maintain a flawless aesthetic appearance. These properties make surface protection film an ideal choice for vehicle maintenance, display protection and other sensitive surfaces.

Surface protector film can be a very cost-effective solution in the long term. Foiling helps to avoid surface damage that may later require major repairs. Those who regularly apply surface protection film can experience a reduction in maintenance costs as the film effectively protects surfaces, reducing repair and painting costs. This can provide long-term monetary benefits while preserving valuable or sensitive surfaces.

Practical, and easy to apply and remove. Here's how to use surface protection films in general.

Steps for applying surface protector film

There are a few key steps in the surface protection film application process, which we will discuss below. It should be noted that, of course, there may be variations and specific procedures depending on the purpose, but typically the following path is followed by the film until it is applied to the surface.

Basic preparation steps

Clean the surface thoroughly before applying the film. This includes removing dust and dirt to ensure that the film adheres perfectly and provides maximum protection. Make sure the surface is dry and free of grease.

Correct use of the film

Precise application of the film is essential for effective protection. Use a special fluid to help align and secure the film to the surface. Make sure that no bubbles or folds remain and smooth out the film.

Care tips to extend the life of your film

Regular maintenance is necessary to ensure the long life of the film. Clean the foil surface with a mild detergent and avoid harsh abrasion or strong chemicals. This will prolong the protective effectiveness and aesthetic appeal of the film.

Surface protection films at Flanker

The films are available in a variety of material qualities and packaging. Here are a few of Flanker's range!

3M™ 8591 Paint Protection Film

This is a clear adhesive film that protects your vehicle's surface from damage, corrosion and wear. It has a thickness of 12 millimetres and is characterised by its ability to withstand extreme weather conditions without staining, shrinking, etc.

3M™ Scotchgard™ SGH6 Paint Protection Film

Used in vehicle protection, this film is a highly durable, long-lasting solution. This is helped by the fact that the Pro Series is shelved with a self-healing formula, meaning that even the smallest damage can self-dissolve from the surface.

Ventureshield™ Paint Protection Film 7510CC/CS

This type of paint protection film is a cost-effective solution for protecting your vehicle's surface from external damage such as stone chipping.

Find more surface protection films in Flanker's online store! Click and have a look!

- Hits: 599