Job safety – all about anti-fatigue cushion matting

There are industries where standing is a vital part of work. Workers must stand for long hours, which is quite stressful for the body. Discomfort and adverse effects can be prevented by using cushion matting. Let's find out what you need to know about these solutions!

Why is too much standing in one place bad for your body?

Standing puts a significant strain on your physical endurance, straining your spine, limbs, neck, back, and joints and can cause muscle pain.

If you stand still for a long time and do not move your legs, the blood-pumping function of the muscles is impaired, leading to swelling and oedema of the legs. Inadequate blood flow can lead to long-term circulatory problems, deterioration of heart function, inflamed blood vessels and dilated varicose veins.

Hard surfaces harm the general condition of the joints, and the bone structure, as the heel, is subjected to a shock-like impact. This is transmitted to the spine, the vertebrae, and the intervertebral disc, and can lead to lumbar strain, sciatica, pinching and even disc herniation.

All this can lead to reduced worker performance, decreased capacity to work and increased fatigue. This has an overall negative effect on work efficiency, which ultimately translates into lost revenue. The pursuit of health and the creation of a comfortable environment is therefore paramount.

What is anti-fatigue matting?

The secret of an anti-fatigue mat lies in its structure. Due to its elastic structure, it provides a slight instability that you don't feel, but it makes your muscles move. This ensures that circulation is unimpeded, not to mention the fact that it dissipates the energy generated when the heel hits the ground, cushioning the impact. Its anti-vibration effect helps prevent the resulting diseases.

How to choose the right anti-fatigue matting?

There are different types of anti-fatigue mats, depending on their resistance to wear and tear, their durability, their material, their thickness, and their softness. Finally, there are also significant differences in the price of the mats. It is important to note that in this case, a higher price typically goes hand in hand with better quality.

Wear and tear resistance of the anti-fatigue matting

One of the most important considerations when selecting is the extent of wear resistance of the material. In this respect, it is not worth saving money, as a carpet chosen for inappropriate use will deteriorate in a much shorter time.

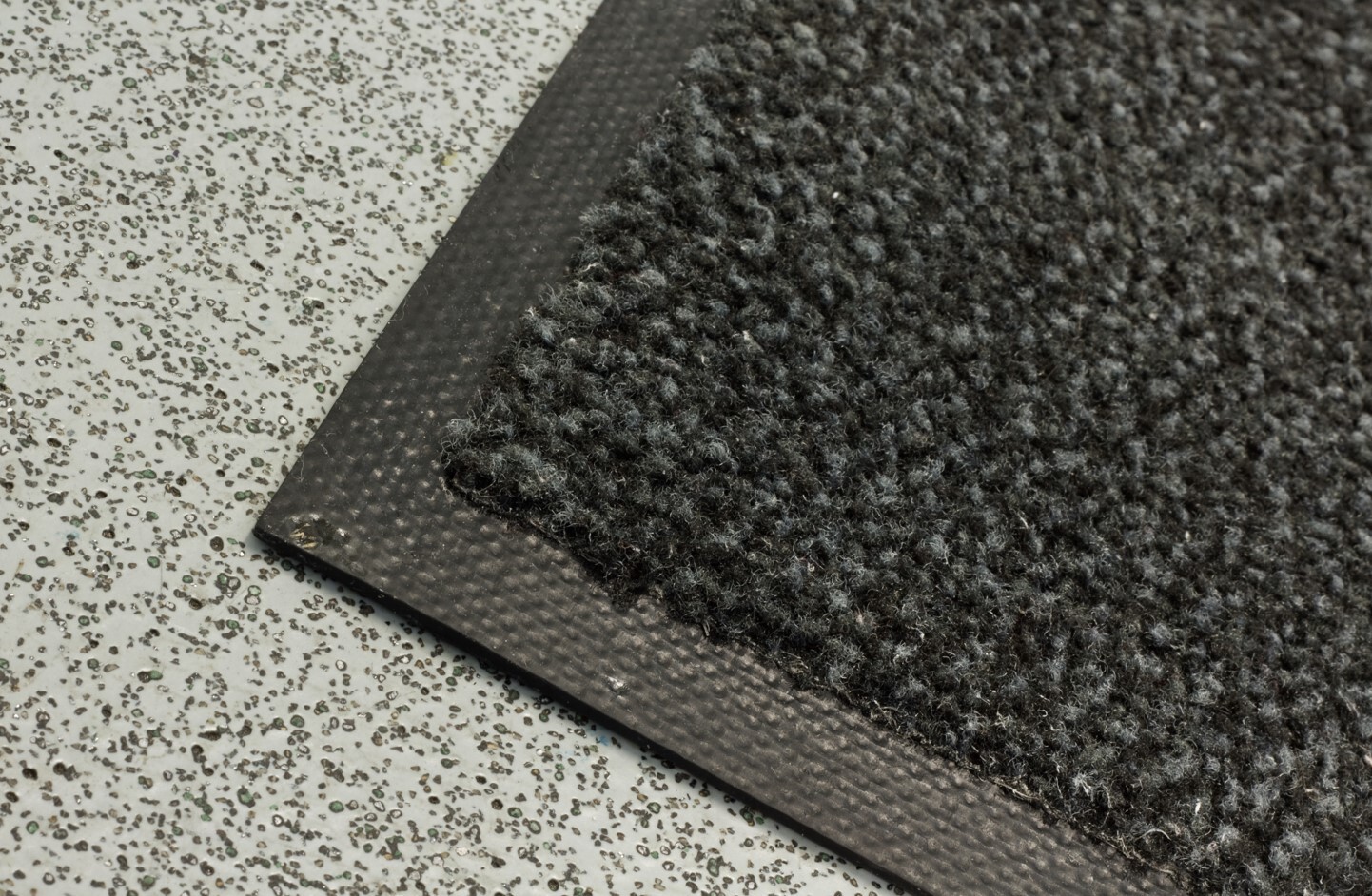

The ideal structure of the anti-fatigue matting

The thickness of the mat itself and the way the layers are constructed are essential. Anti-fatigue matting can be made of rubber, PVC, special types of foam, and chambered-structured, all of which influence how resilient they are and how high their density is. The best ease of standing is achieved if the matting is resilient but not soft. This can be easily checked by pressing your finger into the carpet. It is best if the surface is easy to press into, but the material quickly returns to its original shape, with no finger mark left. Approximately 9 mm is the limit, below which you should not buy the mat.

The perfect size of the anti-fatigue matting

It's important not to skimp on the size of the carpet, as this can undermine your efforts. If the carpet is too short and/or too narrow, workers can easily step off the mat. In most cases, a width of 90 cm is satisfactory, but on rare occasions, when there is minimal movement, 60 cm is sufficient.

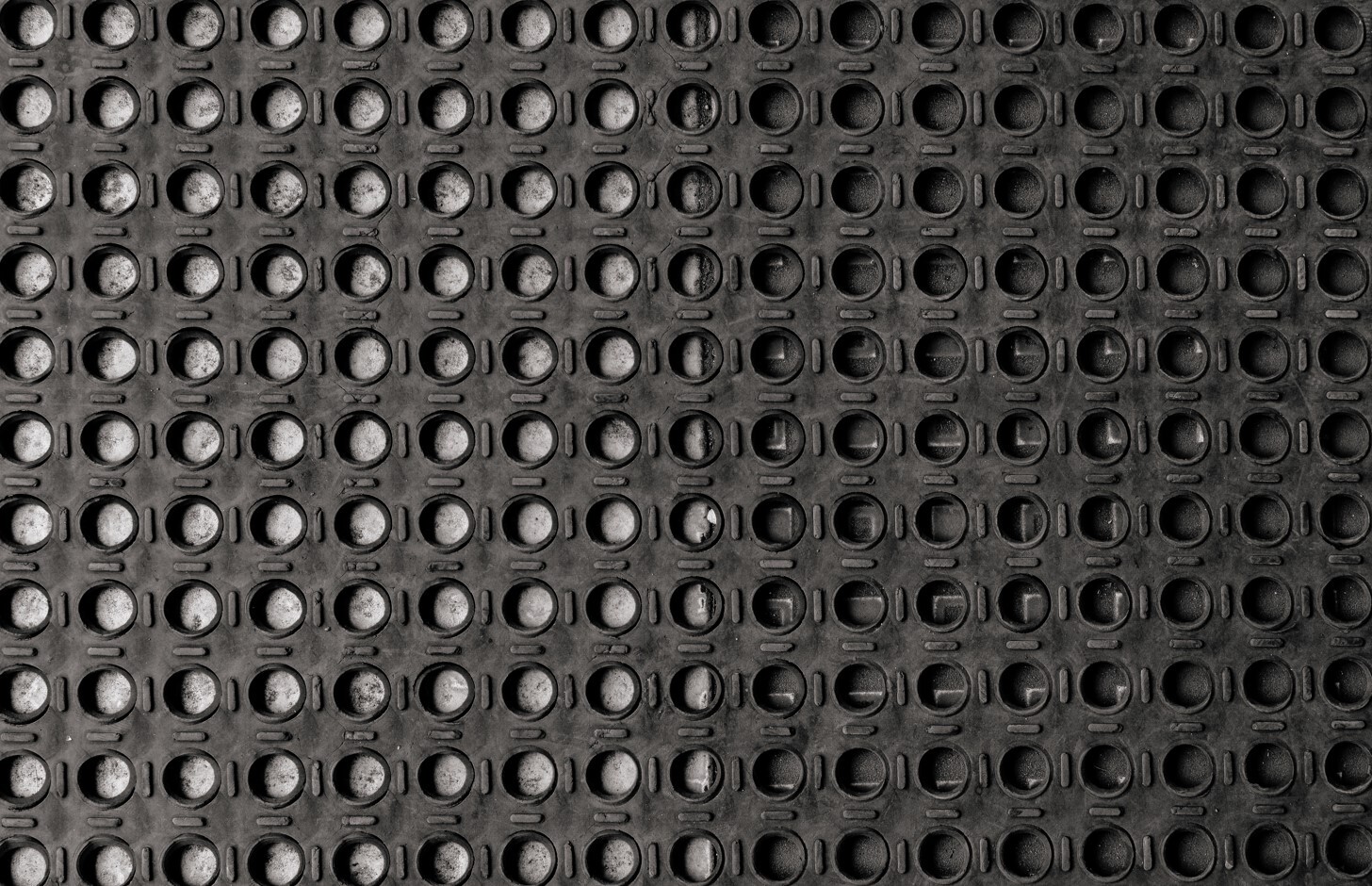

The shape of the anti-fatigue mats

To prevent accidents, mats must fit well and have a good grip. If this is not the case, the risk of tripping increases. The mats can be bought in fixed sizes and rolls, and some mats are made up of interlocking sheets.

The edges and surfaces of the anti-fatigue mats

The edge of the mats is suitable if it is slightly sloping so that the shoes do not get stuck. There is also an alternative solution if the edge of the carpet is not so shaped, as additional elements are available to seal the edge of each mat properly. As regards the surface, the slip-resistance aspect should be a priority: the anti-slip surface should never be sacrificed.

Design options

Both perforated and full mats have their advantages. The former is recommended if there is a possibility of liquid flowing under the carpet, as the material does not stop underneath, but flows out. Cleanability is also important, as well as whether the carpet is intended for indoor or outdoor use. If the carpet is resistant to chemicals and oils, it is also suitable for special applications.

Wondering what kind of anti-fatigue mats Flanker has to offer? Visit our website for more!

- Hits: 725